Material Handling & Fulfillment

Roll Forming Solutions for Automated Warehouses and Micro-Fulfillment Centers

We use our roll forming expertise and extensive global connections to help you move materials around the world.

Material Handling Roll Former

We understand that the effective and efficient movement and storage of products and parts is essential to satisfying your end consumer. As an automated supply chain solution provider, that’s exactly what Roll Forming Corporation strives to help you achieve.

Profile Solutions for Various Fulfillment Systems

Structural Metal Racking Solutions Provider

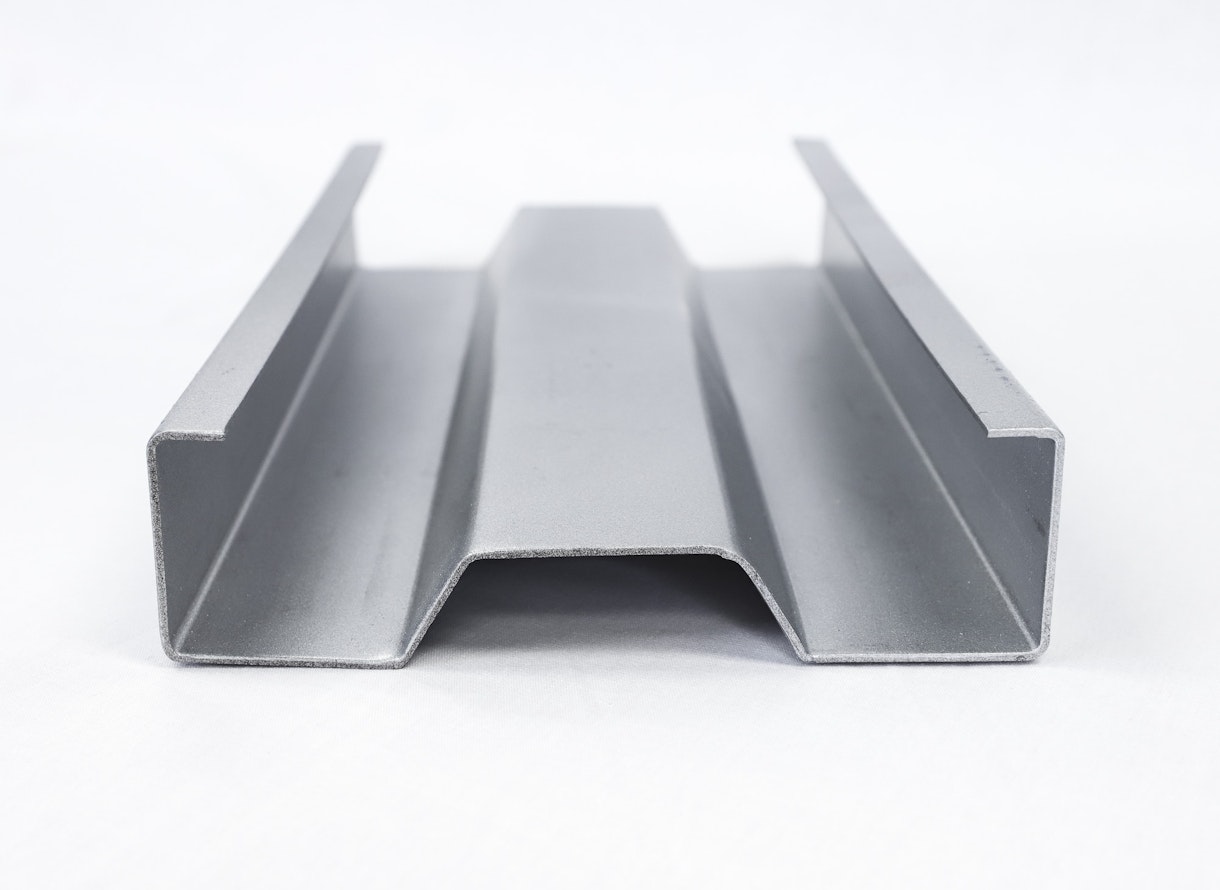

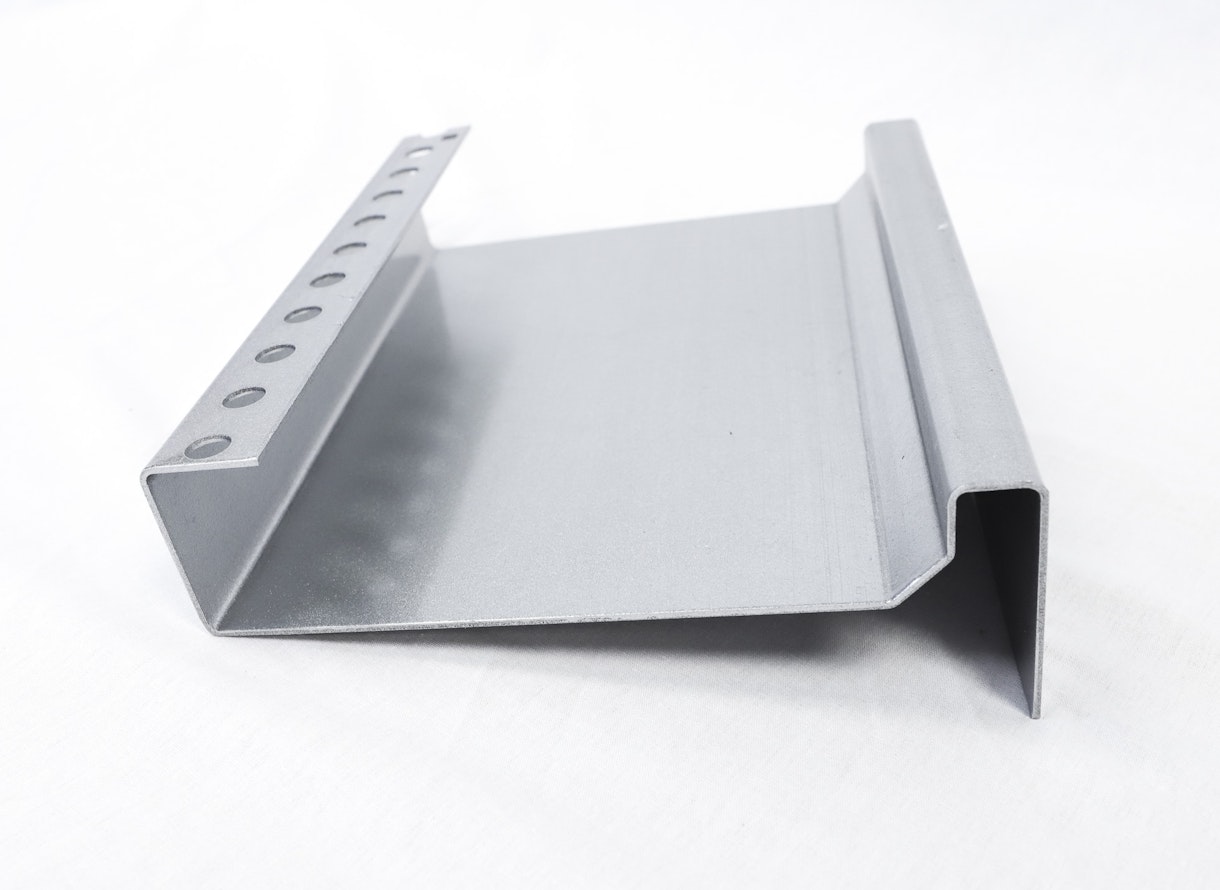

The material handling industry is transitioning from the basic pallet rack system to Automatic Storage and Retrieval System (ASRS). The need has arisen for long-length steel profiles that can be formed to precise tolerances. Many of these profiles also need detailed hole patterns and end configurations. RFC has the in-house capabilities and the capacity to create these customized products efficiently and cost-effectively. We also have the flexibility to change patterns within the products that we produce. With even the most complex designs and exacting specifications, we’ll make sure you get the optimal solution for your application.

Roll Forming Solutions for Automated Supply Chain Systems

We have decades of experience producing for some of the country’s largest conveyor manufacturers, racking companies and system integrators. Our affiliation with the globally based voestalpine Group gives us access to world-class material handling solutions. We have the expertise and the technology to produce parts in both ferrous and non-ferrous metals.

Standard to Custom Metal Components for E-Commerce Warehousing

We have the ability to produce a wide range of profiles from standard commodity shapes to highly customized profiles. Our engineering services allow for product design changes so that we deliver a customized roll formed shape solving your design issues. We co engineer steel and metal components and solutions for smart warehousing technologies and systems. Whether its for automated guided vehicles, ASRS, shuttle systems, pallet racks or conveyors, we have a customized roll forming solution for you.

Our advanced roll forming capabilities deliver high-quality solutions and optimize warehouse space for flexible material handling applications.

Precision and Structural Roll Formed Metal Components for Material Handling Systems and Automated Storage Warehouses

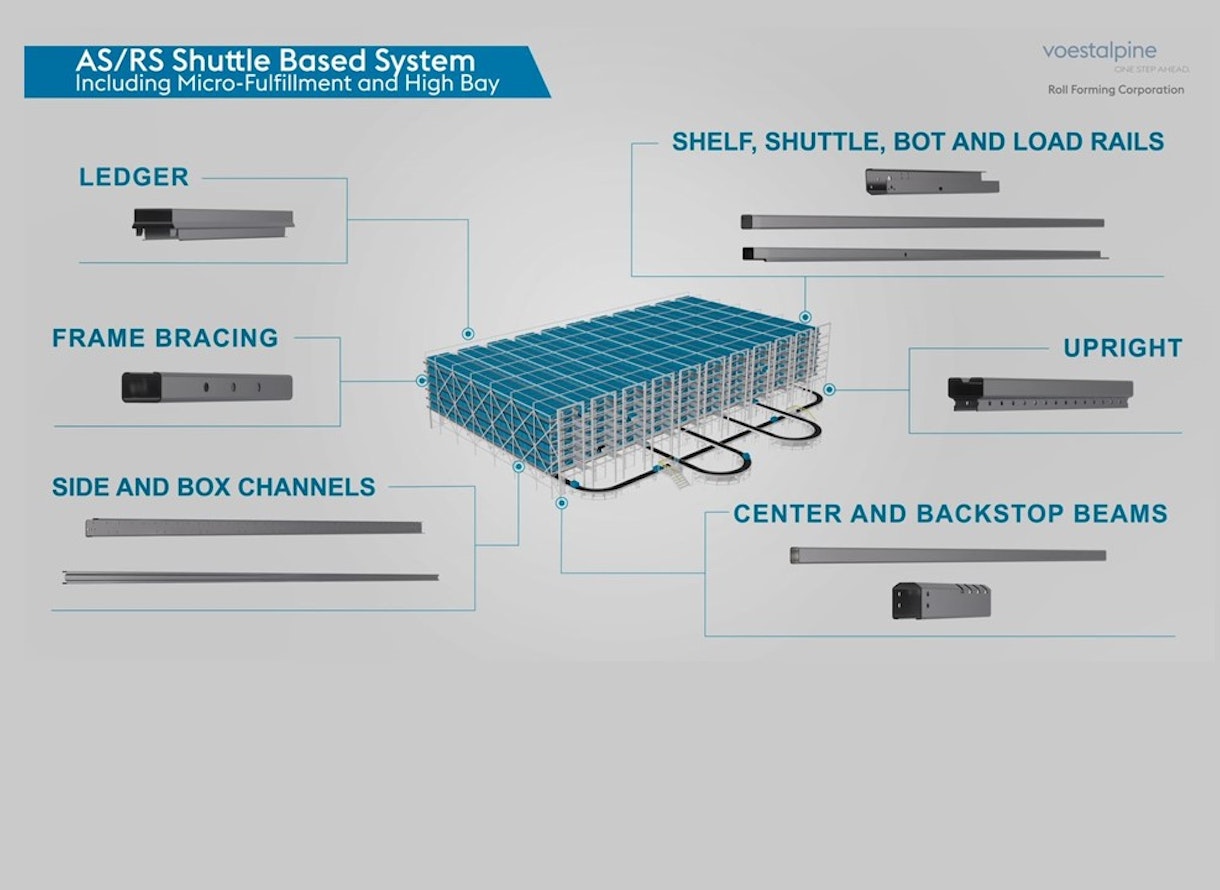

- Custom structural components for AS/RS shuttle systems

- AS/RS racks, aisle and shelve components

- Miniload

- Mini-shuttle robotic systems

- Sigma sections

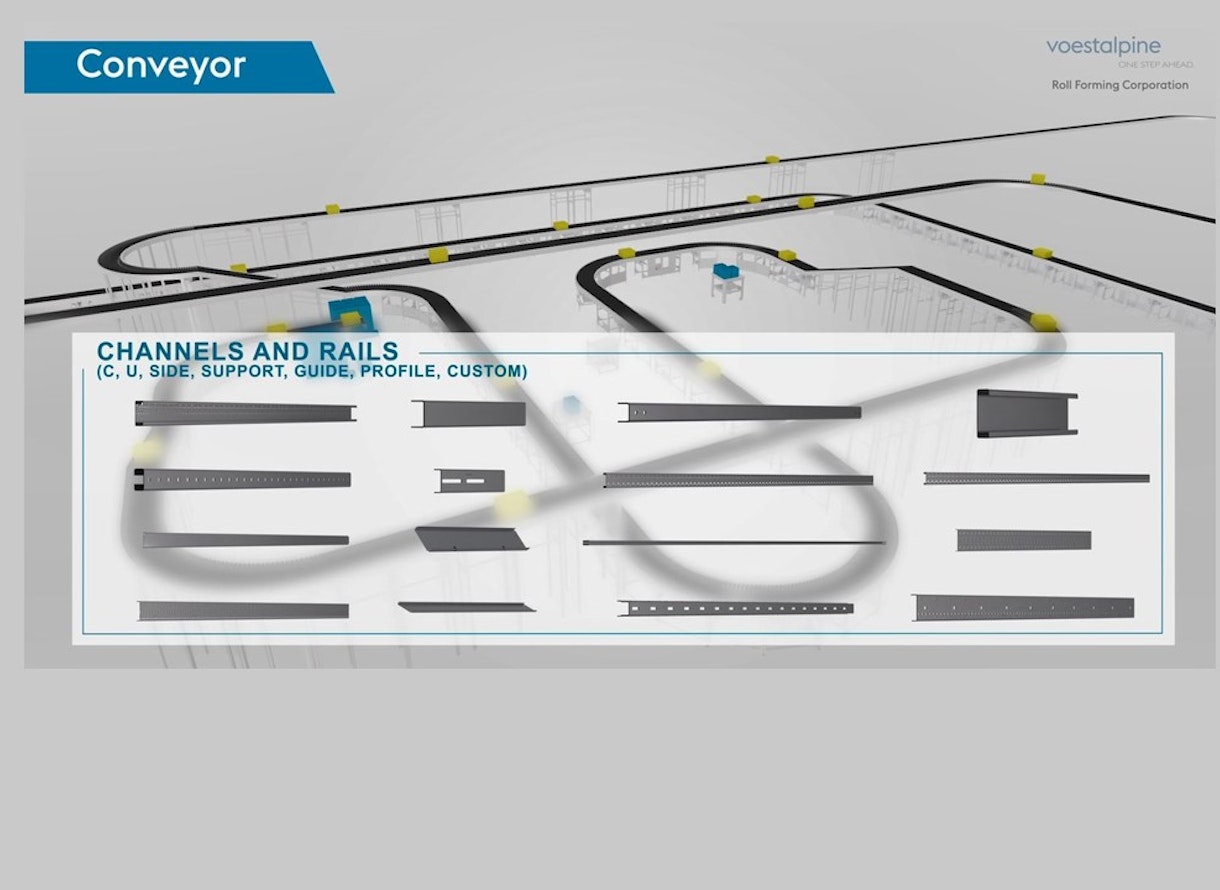

- Conveyor channels

- Conveyor tracks

- Conveyor rails

- Load rails

- Flow rails

- Satellite rails

- Satellite systems

- Pallet racks

- Drive through racks

- Drive in racks

- Push back racks

- Sliding racks

- Stacking frames

- Conveyance systems components

- Robotic delivery system components

- Side guides

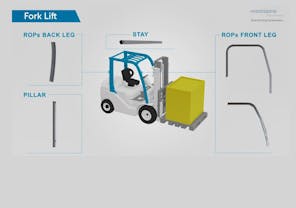

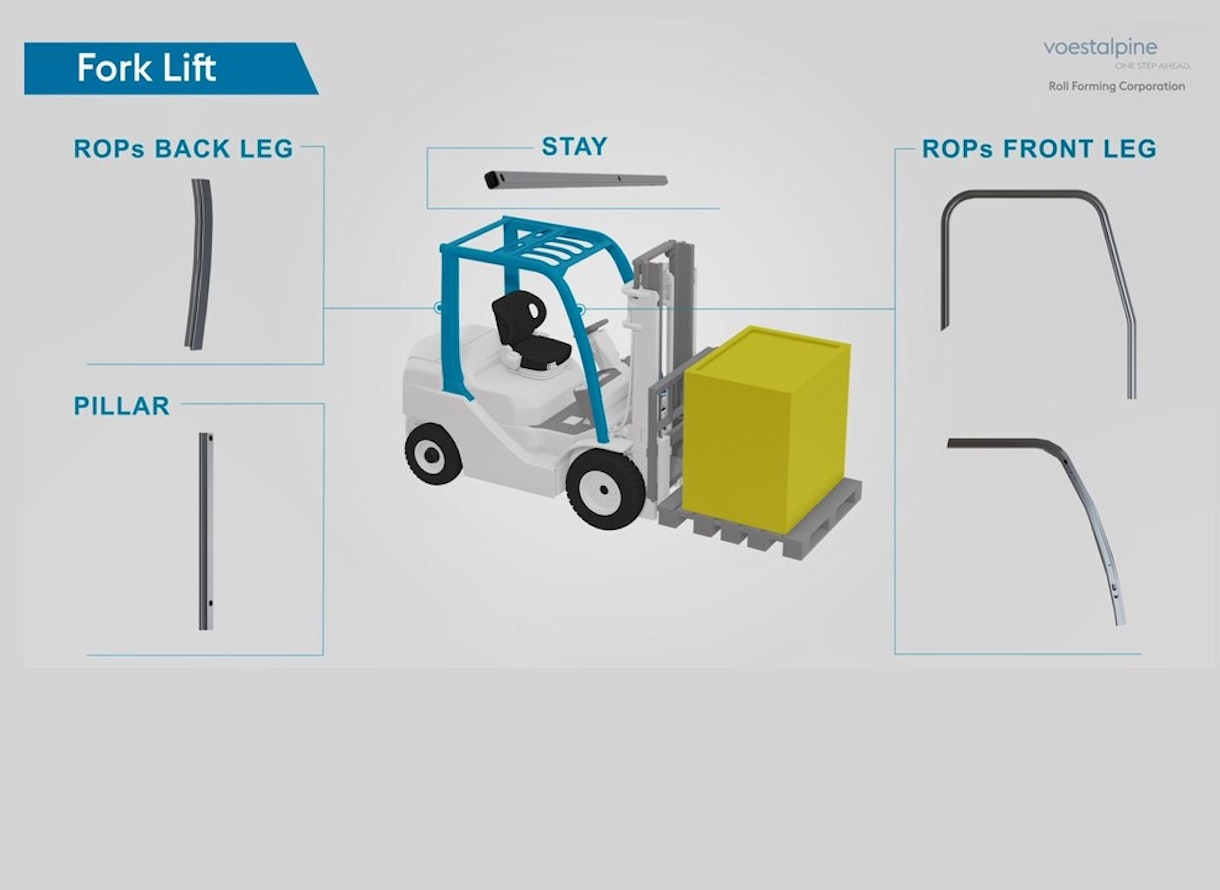

- Forklifts

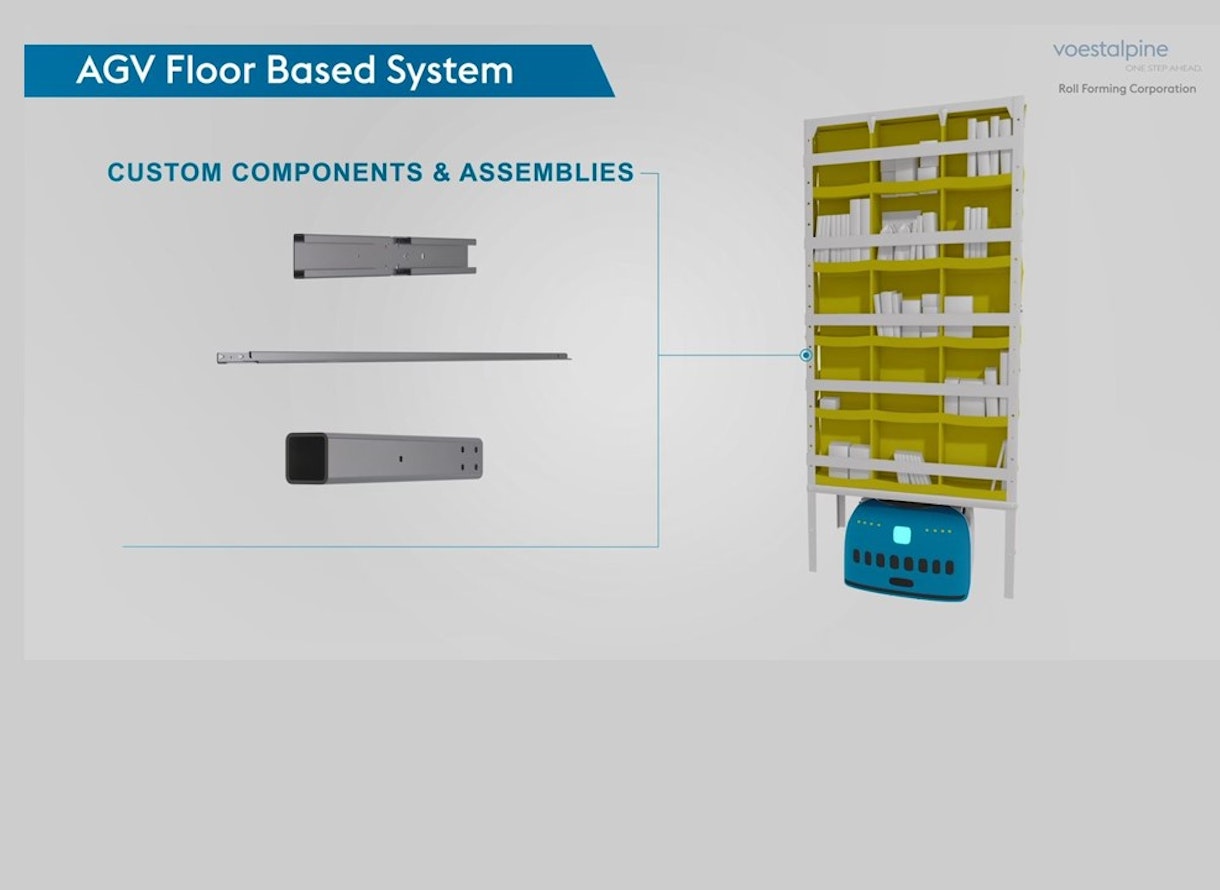

- AGV components

- Self driving technology components and metal integrations

- Structural racking components

- Welded assemblies

- Other customized metal components for automated supply chain systems

Material Handling Roll Formed Profile Solutions

At voestalpine Roll Forming Corporation, we specialize in providing innovative solutions for material handling using roll forming technology. Our team of experts utilizes this highly efficient forming method to create custom-designed components that are structural, tightly toleranced, and perfectly integrated for the demands of material handling and automated storage and retrieval systems (AS/RS). With our precise and consistent roll forming process, we are able to produce complex shapes and profiles that meet the specific requirements of our clients’ material handling systems. This allows us to offer cost-effective and efficient solutions for a wide range of applications, from pallet racking and conveyors to shelving and storage systems to robotics and automated storage and retrieval systems (AS/RS) solutions. We are proud to be a leader in the roll forming industry and are committed to delivering top-quality products that exceed our clients’ expectations.

Roll Forming for Automated Picking Systems

RFC is a leading company that specializes in customized solutions for automated storage warehouses. We utilize the innovative process of roll forming and adjacent technology processes to create high-quality and durable storage components for these facilities. Roll forming allows us to efficiently manufacture various types of custom profile and assembly solutions including u channels, c channels, bot rails, flow rails, load rails, sigmas, beams, uprights, bracing, ledgers, struts, track supports, multi-part assemblies and more custom solutions.

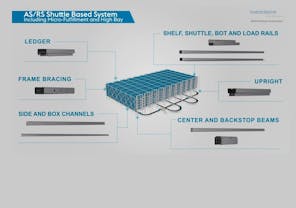

Automated Storage and Retrieval System (AS/RS) Shuttle Based Roll Formed Profile and Component Solutions

RFC offers state-of-the-art custom component solutions for AS/RS systems including pallet, post and parcel, mini-load and multi-shuttle based systems in the material handling industry. Whether you need to improve part quality, reduce tolerances, increase dimensional accuracy to meet your system requirements and customer demand for better pick rates. With a focus on customization, our team works closely with each client to understand their unique needs and develop a tailored solution that maximizes their AS/RS system’s capabilities. Backed by years of experience and a commitment to excellence, RFC is your partner for value added, reliable, and high-performing AS/RS component solutions.

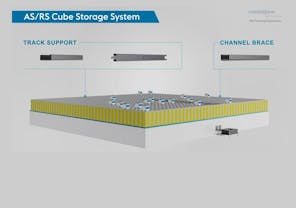

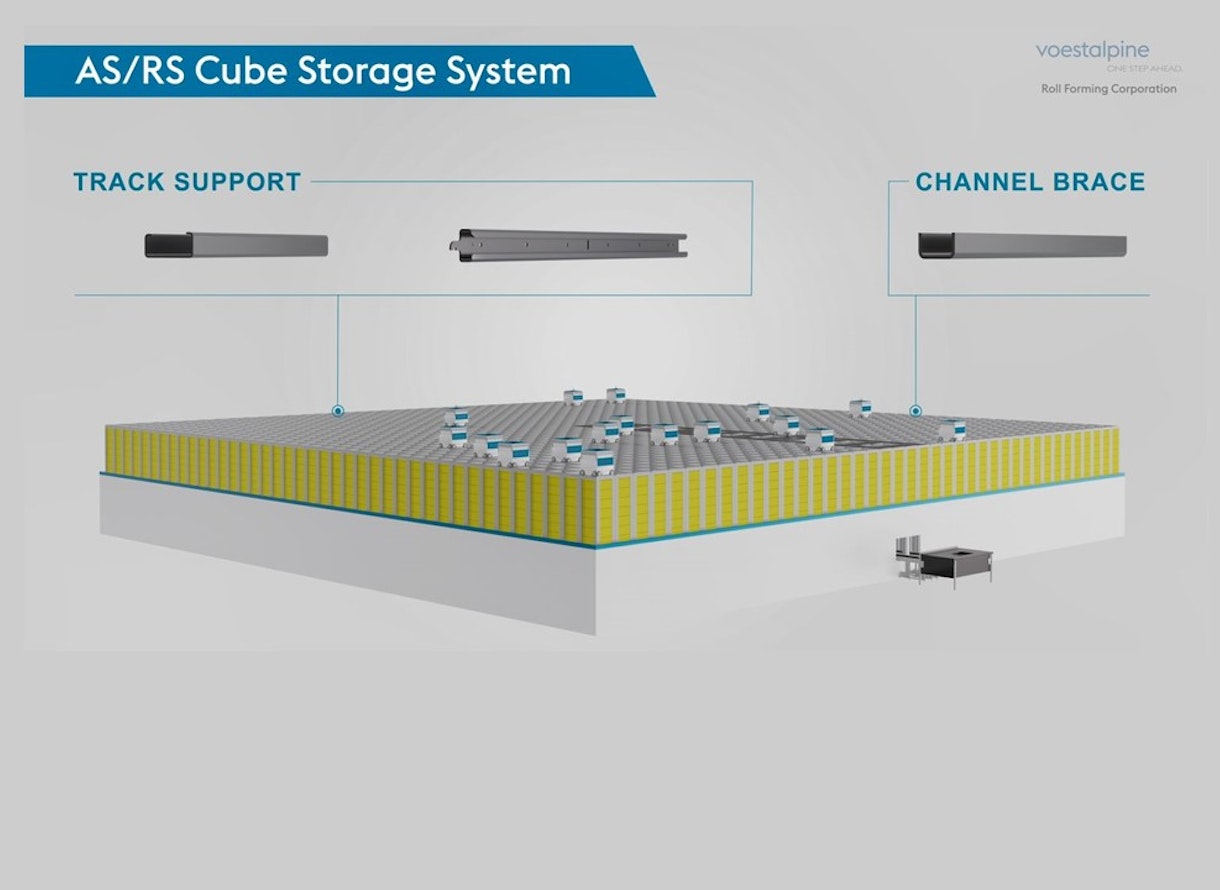

Automated Storage and Retrieval System (AS/RS) Cube Storage Roll Formed Profile and Component Solutions

RFC is a leading provider of customized cube storage component solutions for AS/RS systems in the material handling industry. Our innovative processes and mature materials supply chain ensure optimal efficiency and scalability for growing market demands and customer needs. We understand that every warehouse has unique requirements, which is why we offer personalized solutions tailored to the specific needs of each customer. Our team of experienced professionals works closely with clients to manufacture cube storage components for their AS/RS systems, maximizing warehouse space and increasing pick rates. With RFC’s custom roll formed parts, companies can achieve seamless and efficient material handling systems, leading to improved bottom-line results.

Automated Guided Vehicle (AGV) Floor Based System Roll Formed Profile and Component Solutions

RFC prides itself on being a reliable and innovative manufacturer of components for floor based AGV systems, specifically designed for the material handling industry. Our team of experts works tirelessly to produce high-quality components that ensure smooth and efficient operation of AGVs in warehouse and automated picking system environments. We utilize the latest roll forming and adjacent technology processes to create durable and reliable components that can withstand the demanding requirements of material handling system environments. Our commitment to excellence and continuous improvement has made us a trusted partner for companies providing AGV systems. With RFC’s quality components, system providers can stay one step ahead in offering smarter supply chain solutions.

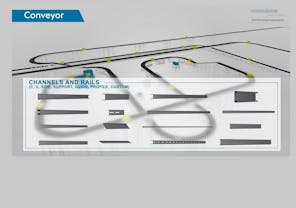

Pallet or Post and Parcel Conveyance Systems Roll Formed Profile and Component Solutions

RFC is a leading manufacturer of components for pallet and parcel conveyance systems, catering to the material handling industry. With our state-of-the-art manufacturing facilities and advanced technologies, we are able to produce high-quality components that are crucial for the smooth functioning of conveyance systems. Our custom roll formed parts are manufactured with precision to withstand the heavy demands of the material handling industry. We are committed to continuously improving our manufacturing processes, delivering reliable and durable components that meet the evolving needs of our clients. At RFC, we take pride in being a trusted partner for companies in the material handling industry, providing them with efficient and value added solutions for their conveyance systems.

Pouch or Pocket Sorter System Roll Formed Profile and Component Solutions

Custom roll formed parts for hanging goods conveyor technology systems offer flexible material strengths, rigidity for heavier pouch requirements, gentle product handling, customized features and precise profile sizing for smooth suspended track system operations optimizing valuable floor space. Batching for odd warehouse layouts with programmable length and features in the roll line help with optimal autonomous pouch or pocket sorter system configuration.

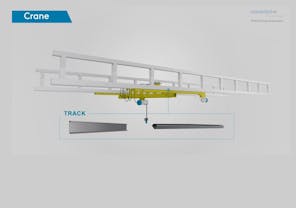

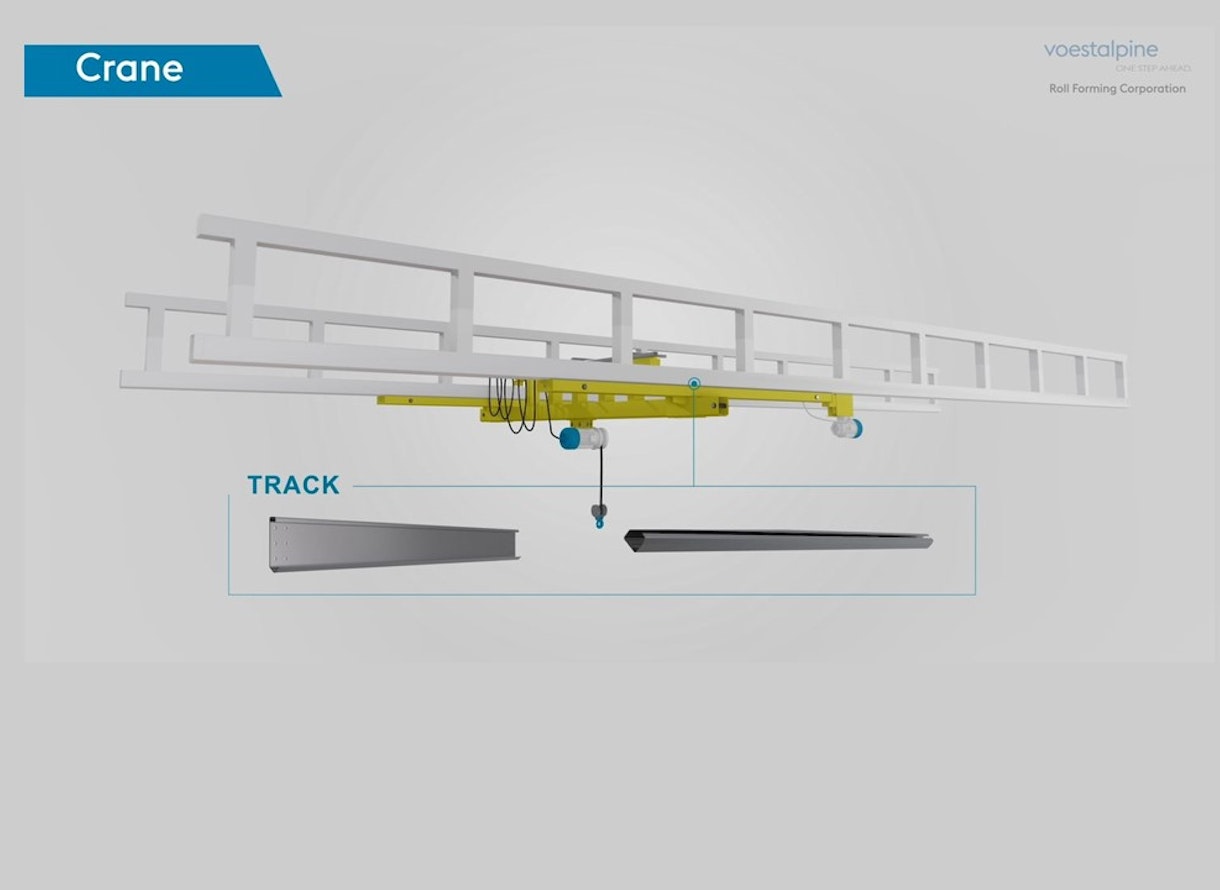

Overhead Crane Roll Formed Profile and Component Solutions

RFC is a leading company in the material handling industry, specializing in the manufacturing of high-quality components for overhead crane systems. Our state-of-the-art facilities and advanced technology processes allow us to produce a wide range of roll formed components including channels, struts, tracks and rails. Our team of skilled engineers and technicians work together to co-engineer and fabricate each component with precision and attention to detail. We prioritize safety, quality, reliability, and efficiency in our manufacturing process to ensure that our components meet the rigorous standards of the material handling industry. RFC is committed to providing our customers with improved performance and functionality of their overhead crane systems.

Kitting and Assembly

As a solutions provider, RFC can engineer and form a design concept that helps to reduce component count and multi part assemblies with an overall custom design that eliminates labor time, costs and frustrations in the field while upholding quality specifications.

Your Automation. Our Structural Metal Components.

At RFC, we understand the importance of efficiency and precision in the material handling industry. That’s why we use roll forming technology to produce high-quality structural metal components and profiles for your automation needs. Our state-of-the-art equipment and experienced team allow us to create customized solutions that meet your exact specifications, providing strength and durability for your automated picking and sorting systems. With our innovative approach to roll forming, we ensure that your automation process runs smoothly and effectively.