Tube Mill

Roll Formed Structural Tubes

Delivering through increased efficiency and capability.

The high efficiency custom tube mill can accommodate welded profiles including standard metric tubes.

Technical Parameters:

- Part Length: 1.5m – 15m

- Length Tolerance: +/- 1mm

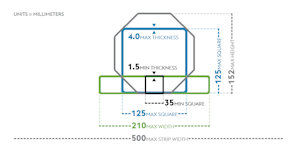

- Material Thickness: 1.5mm – 4mm

- Part Profile Size: 35mm square – 125mm square

- Strip Width: 150mm – 500mm

Direct Roll Forming Method

The direct forming method of the custom tube mill allows for less stress in the material compared to other tube forming methods.

This allows for consistency in secondary forming and welding.

High Quality Tube Processing

Although more efficient in processing, the custom tube mill has the ability to produce straighter, cut to length tubes with customized corner radii.

All Under One Roof

Roll Forming + Welding + Bending + Cutting.

Over the last several years, Roll Forming Corporation has implemented new custom mandrel bending, tube laser cutting and welding technologies alongside the tube mill and roll forming capabilities. Having all of this under one roof allows us to provide solutions to our customers by incorporating our existing secondary services beyond what a traditional roll former can offer.